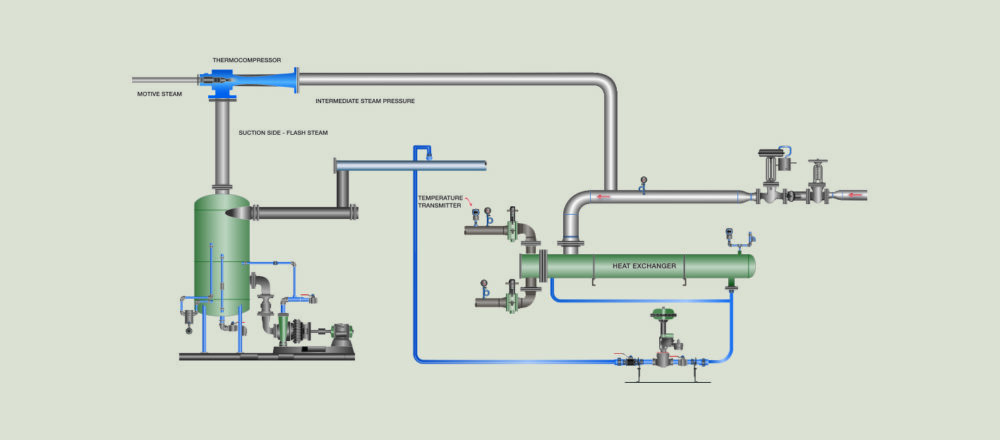

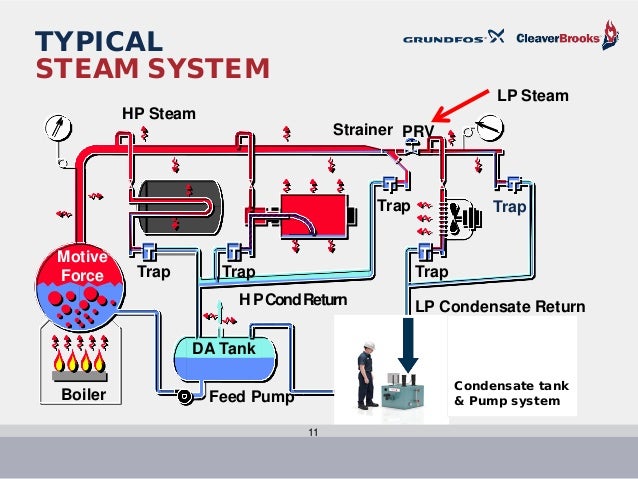

After condensate and flash steam enter the flash vessel the condensate falls by gravity to the base of the vessel from where it is drained via a float trap usually to a vented receiver from where it can be pumped.

Steam condensate tank sizing.

Boiler gross i b r output 840 m b h.

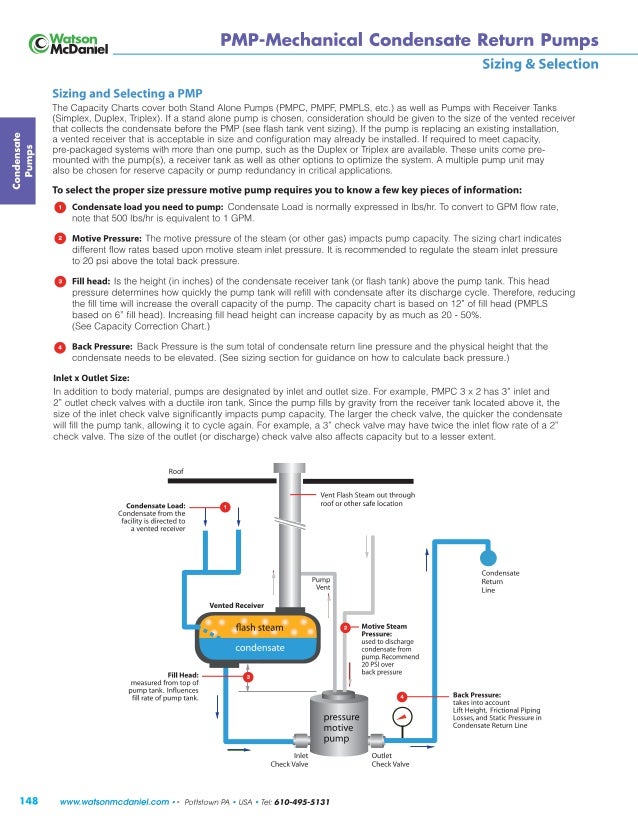

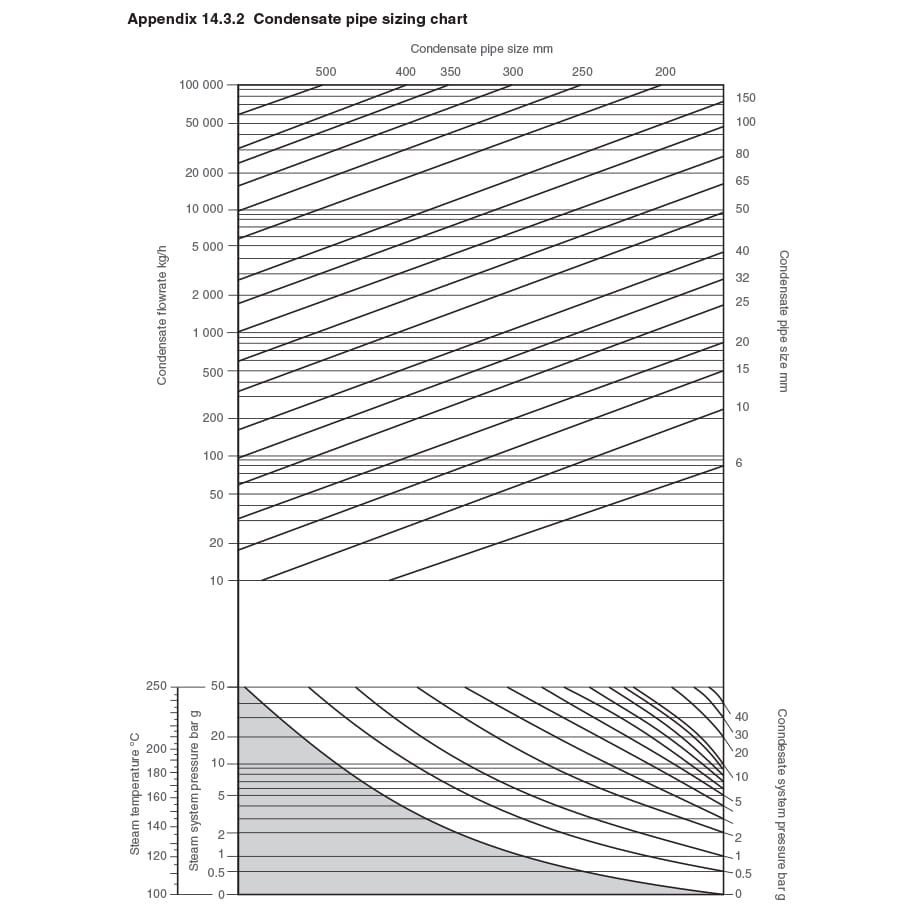

However upon proper application units can be sized at two times 2x the condensing or evaporation rate.

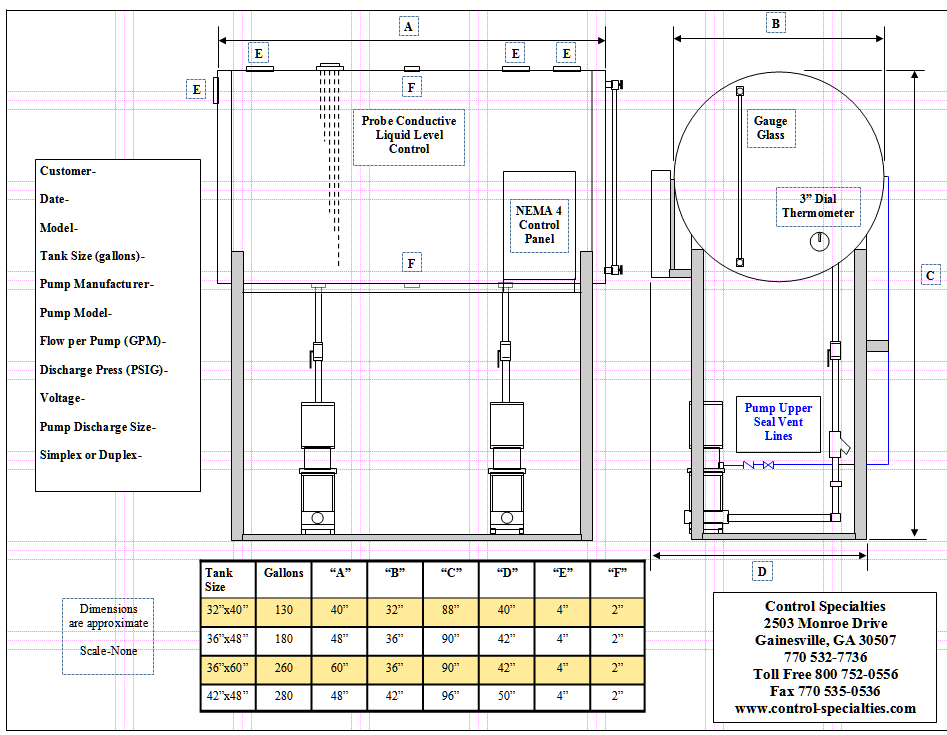

You usually want one minute net storage in a condensate tank.

Steps to designing a flash tank 1.

Consider condensate tank sizing.

Keep in mind that one minute of net storage refers to one minute of pumping capacity in storage.

The amount of condensate entering the tank will be the sum of the steam consuming capacity of all equipment discharging into the condensate return line that is going to the flash tank.

Condensate pumps are typically sized at three times 3x normal condensing or evaporation rate.

Flash tank sizing steam ap 1 1.

Remember the sooner you collect and return condensate the less heat it loses and the less energy required to heat back to steam.

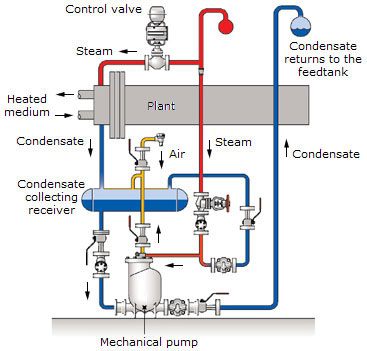

Note that the control to start stop the pumping cycle is on the condensate return unit.

Returning condensate can fill the smaller tank quickly triggering a pumping cycle.

The flash steam in the vessel is piped from the top of the vessel to any appropriate low pressure steam equipment.

Condensate return units are generally smaller fitting their function of collecting steam condensate and pumping it back into the system before too much energy heat is lost.