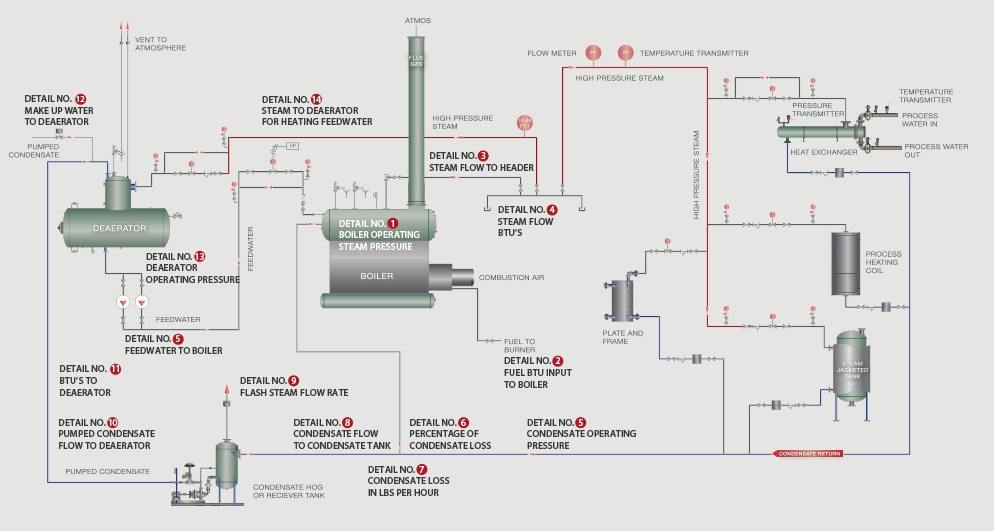

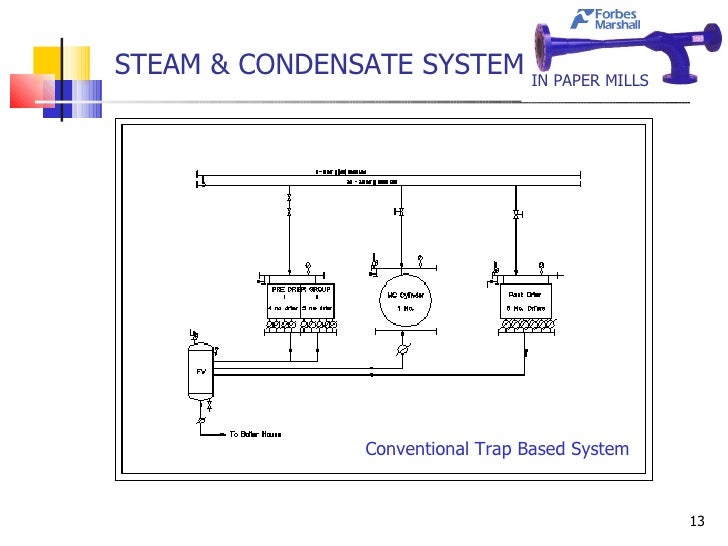

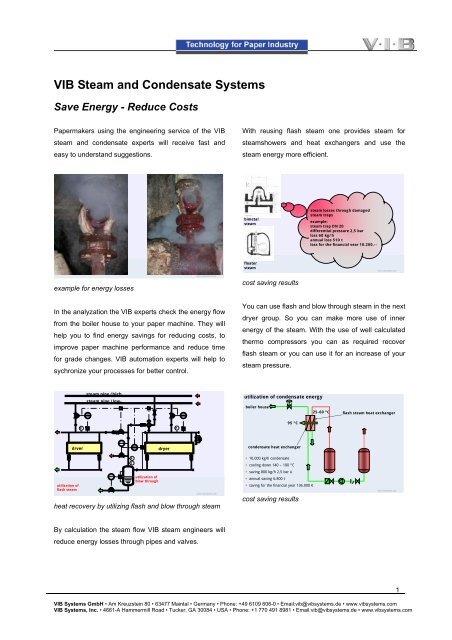

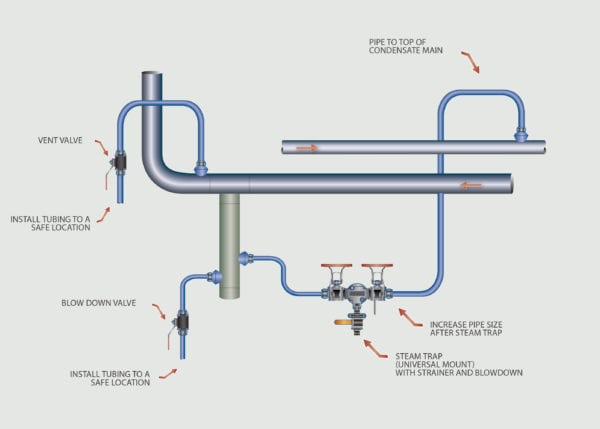

A scheme of a simple open conventional steam condensate system is given in figure 5 6 the steam produced in the boiler house is transported via pipelines to the heat consumers heat exchangers.

Steam and condensate system in paper machine pdf.

In the dryer section the moisture is evaporated as the sheet is pressed between a fabric and the hot drying cylinder.

The first and the last sections of the paper machine usually operate in conditions of vacuum.

This is achieved by means of several steam heated dryers cylinders.

The paper sheet runs over a large number of.

Steam and condensate systems all pulp paper board and the majority of tissue machines have steam and condensate systems.

Berlin www dampfundkondensat de steam and condensate for papermachines e e.

Steam system bureau of energy efficiency 55 syllabus steam system.

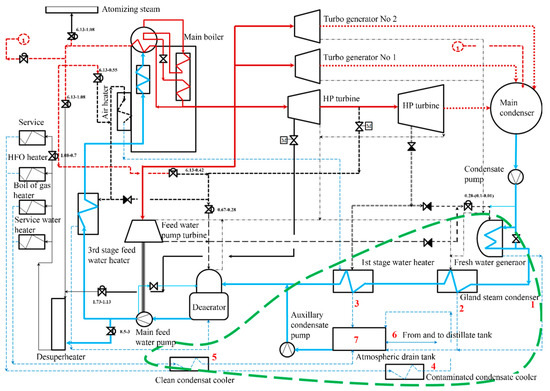

An alternative scheme of a cascade steam condensate system with ejector thermocompression suitable for application in paper machines is given in figure 5 10.

Steam condensate thermal engineering systems are applied in numerous industrial sectors.

3 1 introduction steam has been a popular mode of conveying energy since the industrial.

Properties of steam assessment of steam distribution losses steam leak ages steam trapping condensate and flash steam recovery system identifying opportu nities for energy savings.

These are driven in groups of few together.

The steam and condensate system is a part of a paper machine.

Past the press section the paper sheet has a water content of about 60.

The objective of the steam and condensate system in the paper machine is to provide the steam for the drying.